#2: First functional pedal…for a while at least

Ian saw my prototype and was like “I really think you should reconsider”, but more polite. He told me perhaps the box could be done from copper with silver soldering. I spent ages cutting a copper box and trying to silver solder it. When I finally managed, I was so stoked! I decided to add one more touch by enamelling the top of the box…Put it in the kiln and at 800oC silver soldering melted away and the whole thing crashed and burnt…I was torn apart…

Took a step back and figured the jewellery workshop was a great place to start but I had to go elsewhere if I wanted to carry on with my little project.

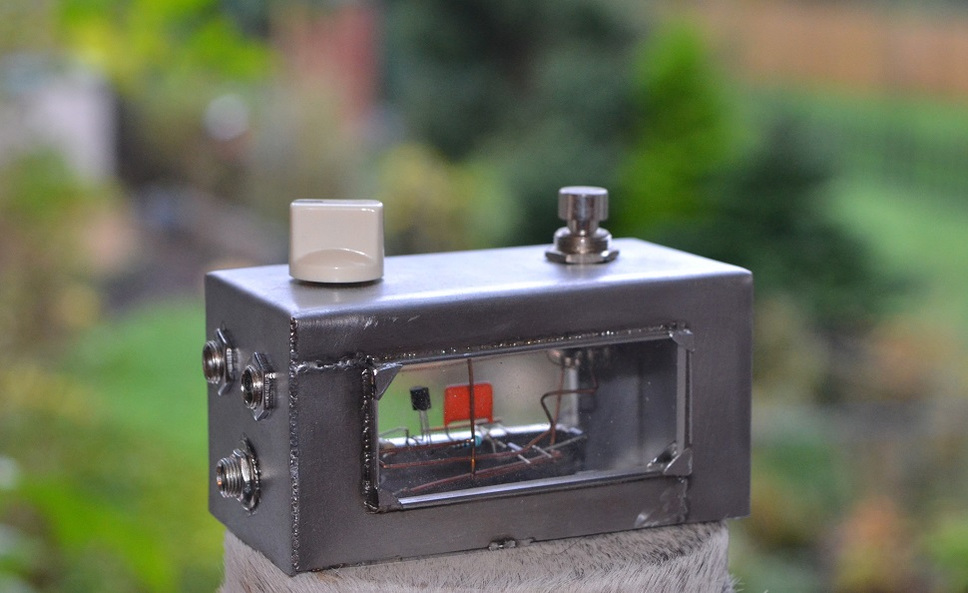

I asked Terry from work to help me out. He introduced me to the notcher. I could now cut the copper sheet in seconds. I was blown away. I joined one of his evening welding classes. I went for TIG welding, bad choice for a beginner. People next to me were welding big blocks of steel and was messing around with tiny bits of copper. It is very hard to weld copper…So I switched to mild steel. Pandemic started, final day before the lockdown I had cut and partly welded 3 steel cases. In June my first functional pedal was complete. It was a single transistor dirty booster.

#3: This one still plays 😊

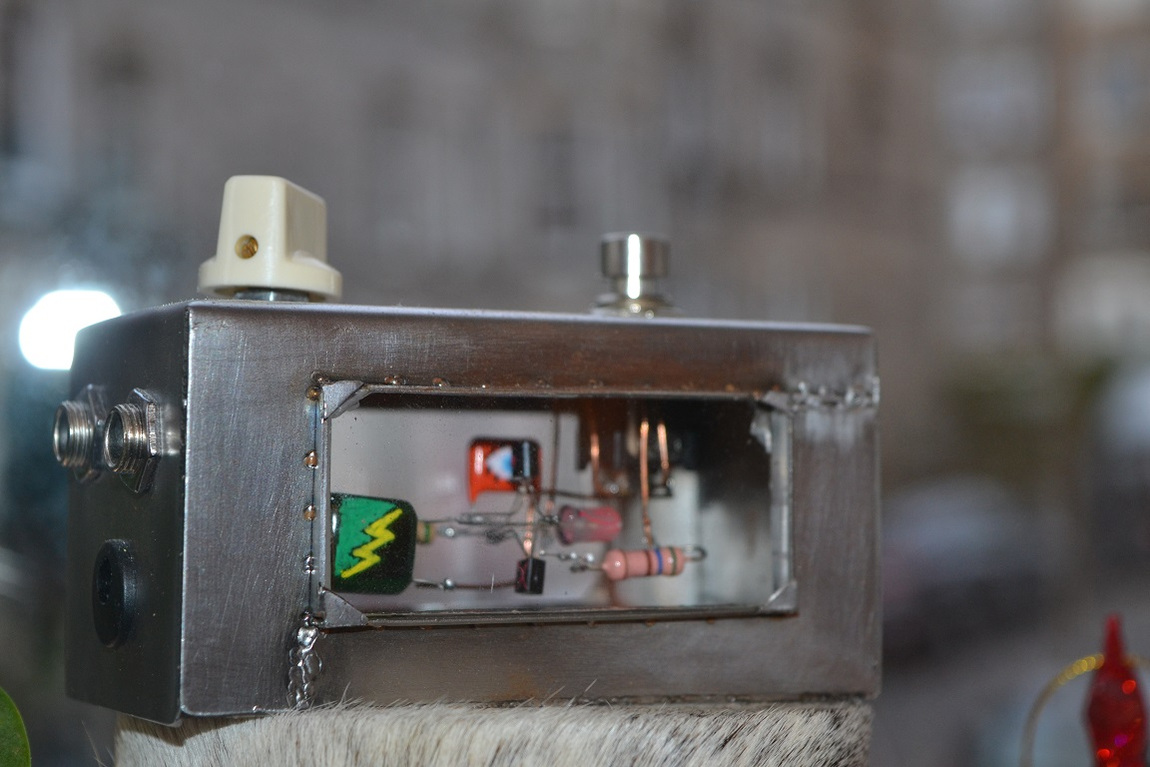

My first functional one was playing for a while, till one day as I was adjusting the potentiometer the whole circuit twisted, and snapped due to my bad soldering and primarily due to the fact that I forgot to cut the small lump from the potentiometer when installing it... Anyway, I was flying to Greece in 3 days and desperately wanted to have something to show to my friends, so I built a second one, wanted to build a 2-transistor fuzz but I had no idea back then about matching transistors so ended up with sort of a dirty boost once again…

Took it back to Athens with me and started showing it, my friends found it awesome looking, showed it to my Zach my cousin and tried it, he played it for a while and told me it has the looks now it needs the sound…So my sound quest begun then.

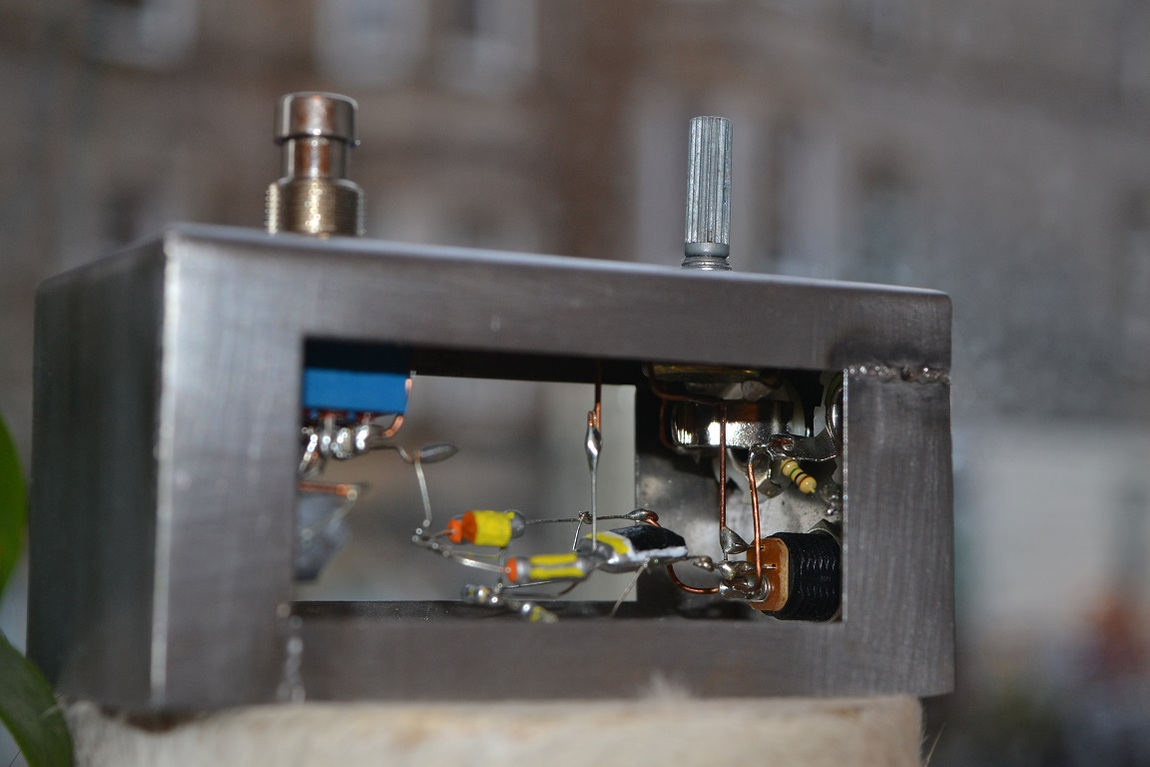

#4: Circuit shaping

While in Greece I had a soldering iron with me some parts and a breadboard, so started trying out different circuits. From the beginning I realised my pedals would be one knobbers, one volume or bias control and that’s it. It was both a personal choice and a necessity, as I had to consider the mechanical integrity of my circuit as well. The more complicated the circuit the easiest it would be to mechanically fail – bend over time due to falls, vibration etc.

So, after the initial enthusiasm a list of things that needed to be done started to emerge. On top of my list was structural integrity, then sound, then everything else. I needed to figure out soldering techniques in order to make my circuits more robust. After lots of experimentation I started figuring out how to arrange the circuit in order to be mechanically solid. While I was doing that the circuits gradually started to take shape. In my head at least…

I never completed the enclosure, as I had already started working on a new design for it. It works fine though.

#4 is a clean boost